- Focus on the spray.xact food system for low-mist processes

- Efficient, safe and reliable production conditions

- New technology is highly sought after on the market

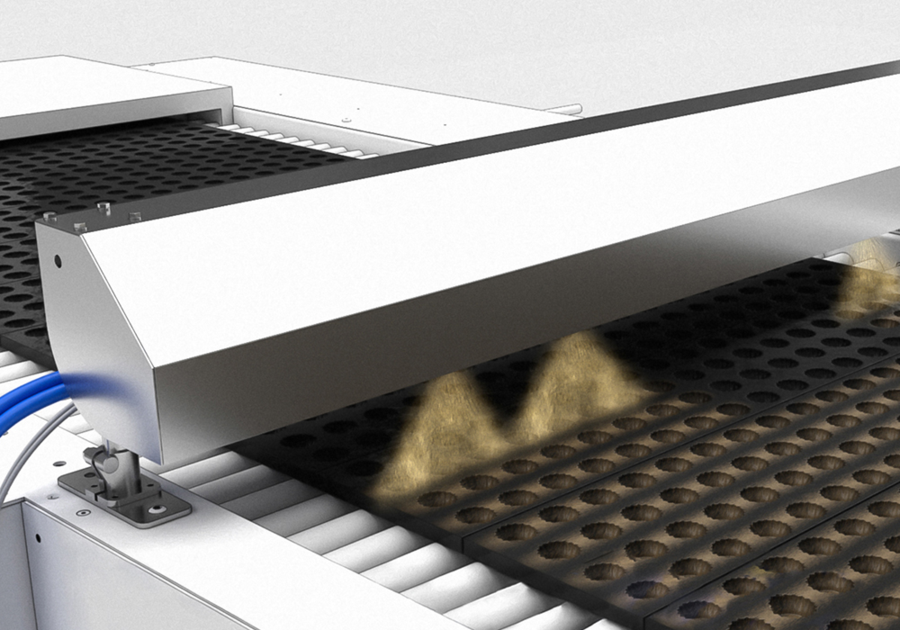

Sustainable, energy-efficient and resource-saving: For its premiere at this year's Anuga FoodTec trade fair, technotrans focuses on its spray.xact food system for the highly efficient spraying of food and technical equipment. At the heart of the system are the proprietary valves developed by technotrans. They operate without compressed air and produce only minimum mist while achieving highly precise results. The technotrans solution, which is already used by several renowned producers, is not only suitable for the treatment of baked goods, frozen food and confectionery but also for the meat industry.

"Our unique spray technology enables a considerable boost in efficiency for the food production sector," explains Hary Kosciesza, Business Development Manager at technotrans. "Companies act cost-consciously and benefit from a high level of production reliability." The extensive features of the spray.xact food system enable stable and highly efficient processes.

Electric pulses instead of expensive compressed air

technotrans' own spray valves, in particular, offer an important advantage for the food producers. Using electric pulses, they are completely airless so that expensive compressed air is a thing of the past. The system dispenses the medium evenly and sparingly, thereby preventing any loss of the medium. "Considering the target of CO2 neutrality, our energy-efficient spraying system achieves optimal results," says Kosciesza.

As the workforce is not exposed to any spray mist, the spray.xact food system ensures perfect compliance with the relevant health and safety standards. In addition, it protects the production equipment against soiling. As a result, the maintenance and cleaning intervals can be extended. Even a complete enclosure can be dispensed with, even an extraction system is no longer required. Moreover, setting the spray system up is extremely easy and covers all of the relevant parameters from the temperature up to the spraying quantity. An optional system for monitoring the nozzles for clogging increases the high level of process reliability even further.

Customised solutions

Thanks to its modular design with food-safe components, the spray.xact food system can be easily integrated into any existing machinery. To this end, technotrans configures the spray system in line with the specific customer requirements. "We offer customised solutions for all types of needs. With our system, food producers can fulfil the ever increasing efficiency, process reliability and product quality requirements," explains Kosciesza.

The solution, which has been in use in other industries for many years, has proved its worth immediately after its market launch. Renowned system manufacturers and food producers rely on the technology made in Sassenberg. In addition to the spray system, the company, which is present at the Anuga FoodTec for the first time, will also showcase various temperature control solutions for a wide range of applications.

technotrans at the Anuga FoodTec 2022: 26-29 April, hall 10.1, stand B041.