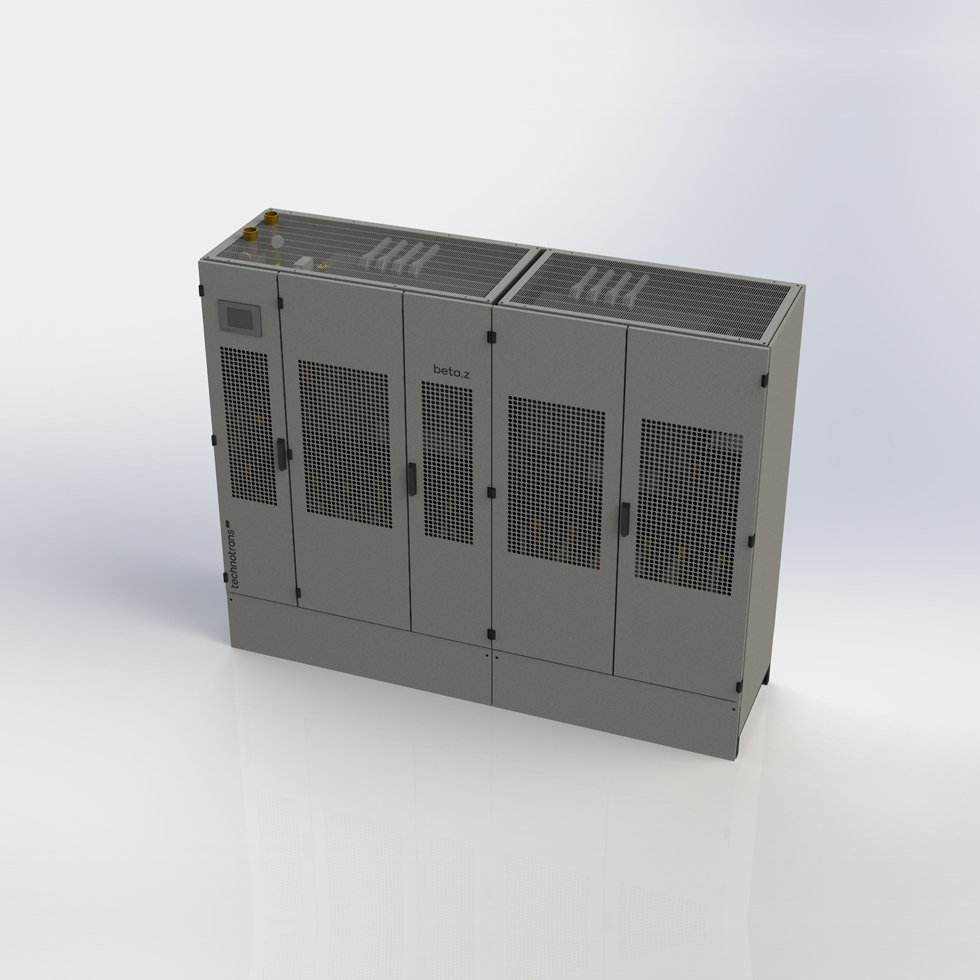

The beta.z individual-zone temperature control system is the ideal solution for sophisticated waterless or conventional printing applications. The system guarantees stable production conditions and enables top-level offset printing. It is particularly suitable for applications involving special inks as well as for IPA-free or IPA-reduced printing. The beta.z unit ensures the precise temperature control of the ink unit at all times. Upon request, the system is also available with an ink roller surface temperature control system based on IR sensors.

The entire system is designed as an atmospherically sealed system offering maximum protection against corrosion and algae. Minimal leaks, e.g. in the area of the rotary cylinder unions, can be compensated for by way of an optional automatic water supply system.

The modern, user-friendly microprocessor control unit with a colour display provides clear insights into the operating and process data.

- Ink units with individual temperature control for perfect ink viscosity

- Ideal for supporting the use of special inks as well as for IPA-free or IPA-reduced printing applications

- Separate circuit and individual temperature control of the ink ductors

- Optional temperature measurement by way of IR sensors in the ink unit

- Optional use of the press speed as the command variable

- Optional water supply system to automatically compensate for minor leaks (e.g. in the area of the rotary union)

- Atmospherically sealed system to prevent operating problems caused by corrosion or algae

- Suitable for combination with a beta.c combination unit with the temperature control circuit being used for supplying the beta.z with cooling water

- Optional extension with additional circuits to supply other cooling locations, e.g. chill rollers, oil cooling systems or water-cooled drives of rotary presses

- Available with 2 to 14 circuits

- Connection to an external cooling water supply via integrated stainless-steel plate heat exchangers (PW version)

- Standard RAL 7031 or RAL 7035 colour (other colours upon request)

- Microprocessor control unit with a colour touch display

- Optional shut-off of individual circuits by way of ball valves in the feed and return flow

- Dirt filters in all individual circuits

- Equipment options:

- Infrared temperature sensors (per circuit)

- Automatic water supply system

- Use of the press speed as the command variable

- Data remote control TP5.7 with a colour touch screen

- Individual connection to the press control station or external data remote control

- And much more