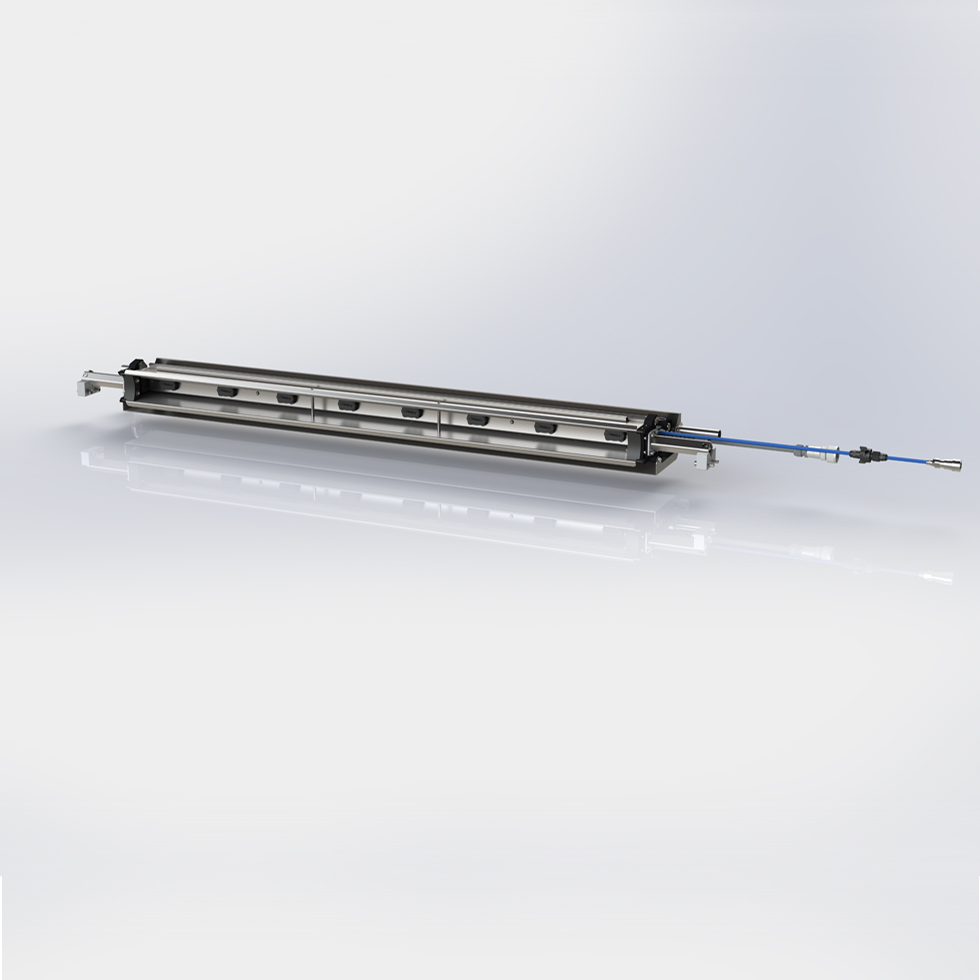

deltaspray

Spray dampening systems with innovative nozzle cleaning system for maximum productivity

Printing process optimised, productivity maximised: The modular spray dampening systems from the deltaspray line enable printers to deliver consistent quality with no loss of high process stability. This is made possible by the innovative and reliable technology inside the systems: deltaspray has an innovative and effective nozzle cleaning system.

Sophisticated structures in the caps of the nozzle produce the so-called Venturi effect, which creates a vacuum. This not only provides the nozzles with protection against dirt, it also maximises machine availability and minimises the time needed for repairs and maintenance.

In addition, individually controllable nozzles and automatic shutters allow highly flexible system configuration. So you can be sure of having total control over the spraying pattern and humidification – at all times and independent of the web width.

- High and controlled spraying frequency

- Dosing via individual activation of each spray nozzle possible

- Increased service life, low operating costs and low installation and maintenance effort thanks to innovative nozzle cleaning system

- Easy and safe operation

- Fast and tool-free nozzle maintenance thanks to bayonet locks

- High level of flexibility in production

- Constant dampening solution temperature

- Durable and robust

- Automatically adjustable shutter available as an option

- Self-powered and low-maintenance nozzle cleaning system

- Modular design supports customer-specific adaptation

- Tool-free maintenance via practical service hatch