Maximum flexibility and outstanding operational reliability: The gamma.line ensures the effective preparation/circulation of the dampening solution in order to fulfil a wide range of requirements of rotary offset presses. The units can be customised and equipped in line with the specific requirements of the user.

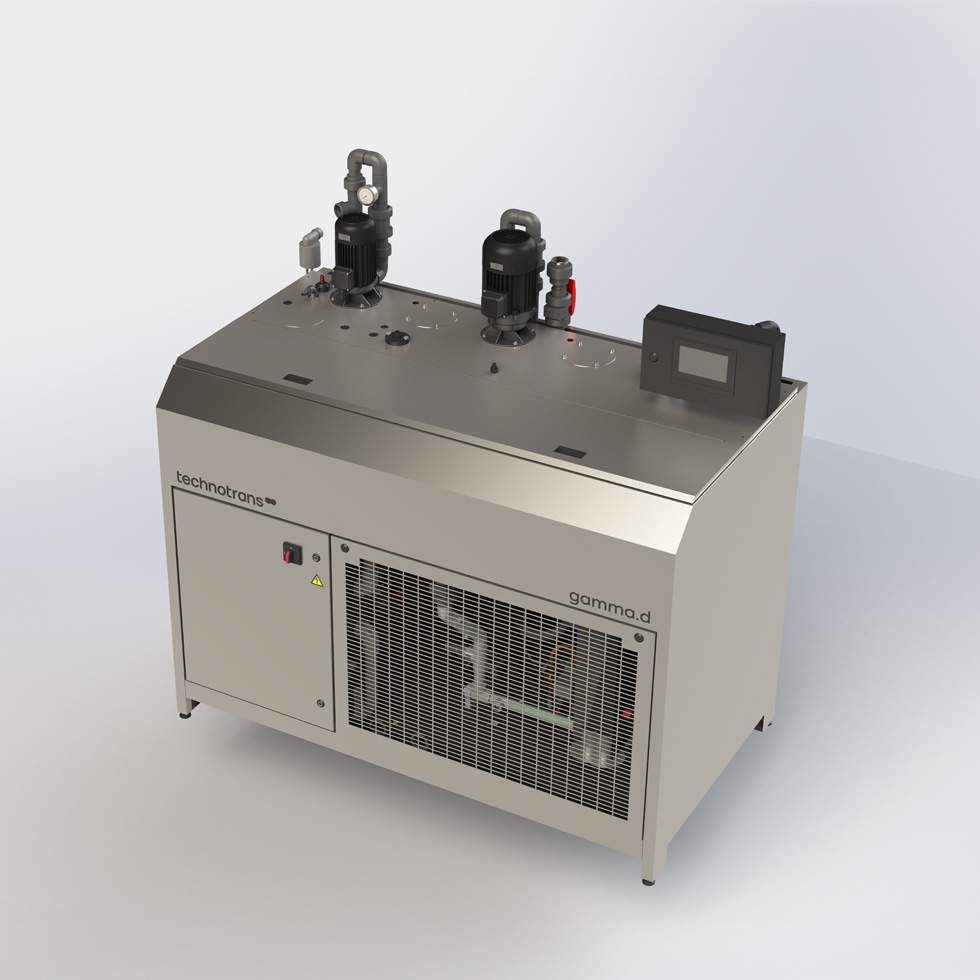

The console-type gamma.d series is available with cooling capacities between 4 kW and 50 kW. Several tank sizes up to a maximum volume of 590 litres are available. The pump system can be optionally equipped with a backup pump and up to two additional feed pumps. The system can be combined with a wide range of prefilter intermediate tank systems or with intermediate tanks with a clarifying system based on a surface skimmer. All of this ensures the optimum supply of the connected dampening solution systems at all times.

Additional equipment options include the fluidos dosing system and several alcohol stabilisers for heatset printing presses with alcohol dampening units. This high level of flexibility is a huge advantage when it comes to the specific requirements of rotary newspaper printing presses.

- ErP-compliant with regard to the Ecodesign directive

- Proven series for rotary offset presses, perfectly adapted to the varying requirements of these printing presses

- Compact, ergonomic and service-friendly design

- High level of operational reliability thanks to high-grade, high-performance components

- Several options for an effective, demand-based dampening solution filtration

- Precise dosing, measuring and control equipment

- High level of flexibility in terms of the set-up and equipment of the system to ensure optimum adaptation to specific press configurations or customer requirements

- Specifically designed for newspaper, heatset and semi-commercial (hybrid) rotary offset presses with continuous-feed, brush-type or turbo dampening systems as well as for central systems for sheet-fed offset presses and/or narrow-web rotary printing presses

- Cooling capacity between 4 kW and 50 kW

- Standard RAL 7031 or RAL 7035 colour (other colours upon request)

- Dampening solution tanks with a volume between 230 l and 590 l maximum, depending on the cooling capacity

- gamma.d 80-300 with one circulation and feed pump, gamma.d 500 with one circulation pump and two feed pumps

- Digital temperature display with an indication of the most important operating states and collective faults

- Three different refrigeration unit variants: with an integrated, air-cooled (up to gamma.d 150) or water-cooled refrigeration unit or with an integrated cooling water/dampening solution plate heat exchanger (PW)

- Equipment options:

- fluidos or digidos.p dosing technology with a consumption measurement system

- alcocontrol or alcosmart DSP system for IPA measurement and control

- Integrated filter station for filter mats or a softflow filter solution

- Microprocessor control system with a colour touch display, ready for web/browser visualisation and remote maintenance

- Data interface for control station connection

- Conductivity and/or pH display

- Customisable pump system with sealless submersible pumps

- Quick draining function with an additional pump

- Hot-water flushing unit (not available in combination with an alcohol stabiliser)

- Version in accordance with UL 508 A, NFPA 70/79

- And much more