Precise, economical and reliable in production: spray.xact is the new generation of spray lubrication solutions. This highly flexible solution is ideal for the contact-free and precise application of oils and many other media. The spray jet is produced with a high-frequency valve with a 1-substance nozzle.

The advantage compared to conventional, compressed-air operated solutions: no unwanted mist and no need for an extraction system. These characteristics make spray.xact an economical and low-wear and low-maintenance solution which is suitable for use in a whole range of fields – for example, for punching and forming applications, fine blanking and for rolling mills. Depending on the specific order, technotrans offers various different solutions: thanks to its flexible modular design, spray.xact b is ideal for retrofitting and re-equipping under limited spatial conditions.

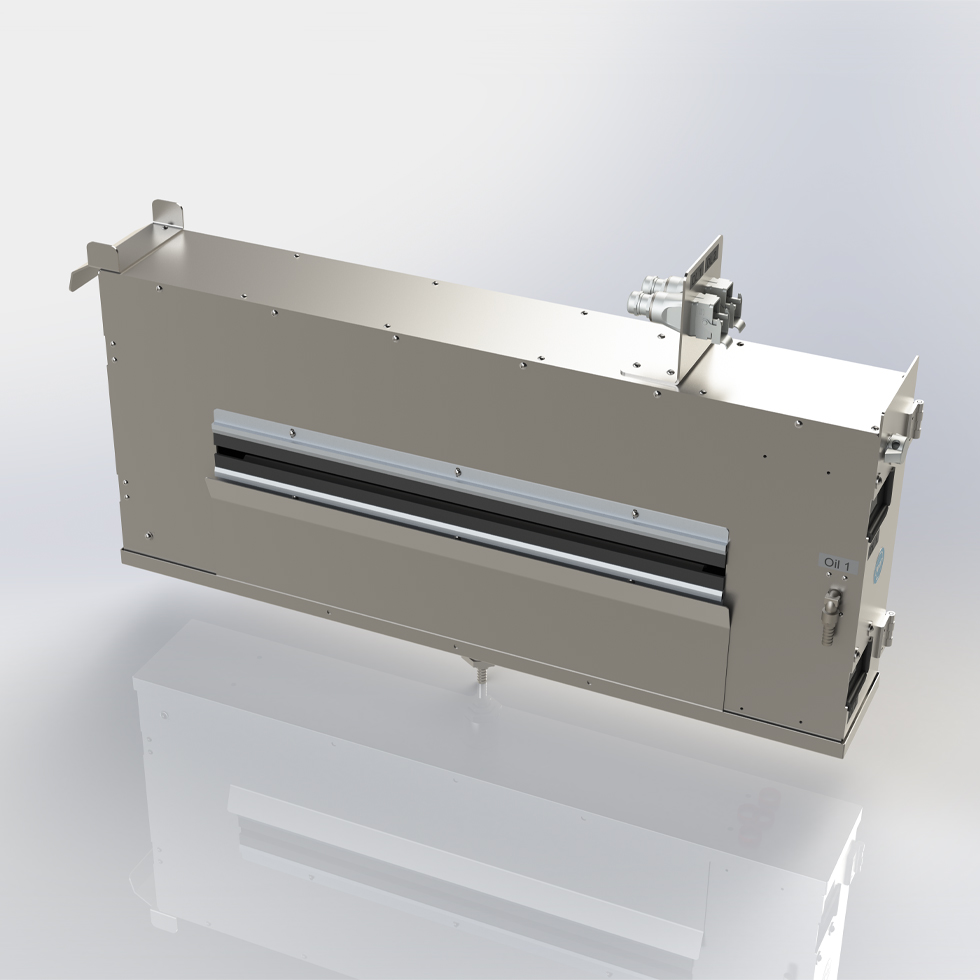

The compact spray.xact c on the other hand is a spray unit in a nearly closed stainless steel housing which is particularly notable for its service-friendly features. The spray.xact spray units are supplied and controlled via the spray.xact fs.

- The prevention of spray mist results in reduced plant contamination, reduced contamination of the ambient air and eliminates the need for an extraction system

- Reduced health hazard for operators

- Extremely precise and economically efficient oil application

- User-friendly control

- Compact, clearly structured design

- Low-wear and low-maintenance

- Process and production reliability: Fault signals and error logs

- spray.xact b is the flexible solution for the oiling of circular blanks, standard blanks and coils

- Flexible in use: Different levels of spray intensity from each nozzle, if necessary, and easy activation and deactivation of individual valves possible

- Low tubing and cabling expense, independent of the number of nozzles

- Can be easily integrated into the machine as a whole

- Spraying width up to 2000 mm (size on request)

- spray.xact c with a nearly closed spraying chamber is ideally suitable for precise spray lubrication

- Spray bars in a stainless steel housing (telescopic design)

- Coil width < 600 mm: Removable spray bars for maintenance purposes

- Coil width > 600 mm: Spray bars can be pulled out via telescopic rails

- spray.xact fs mobile is a compact and flexible system comprised of a control system, supply system and spray unit

- Media supply via pump module with suction lance or pressure tank (20 l)

- Control system as control cabinet (also mobile) or control panel

- 7" colour touchscreen with connecting cable

- Up to 250 spray programs can be saved

- Profibus or Profinet connection