Up to 2 x 48 nozzles for a maximum spraying width of 4,800 mm – those are the dimensions for which spray.xact 5000 was created. The special spray lubrication system for large presses provides for airless and economical oil application to blanks which are the preferred solution for the outer skin panels of vehicle bodies.

The heart of the system is the proprietary spray valve developed by technotrans. It is electronically controlled and emits spray pulses. Thanks to a high spraying frequency, the result is a constant and homogeneous spray pattern on the sheet metal surface. There is also no need for an extraction system. The oil quantity can be adjusted precisely simply by changing the spraying parameters. In addition, adjustment is completely straightforward due to the fact that it is 100% electronically controlled.

Furthermore, spray.xact 5000 excels thanks to its easy access to all of the components for maintenance or in the event of malfunctions and straightforward installation of key components for the emergency mode.

- Spraying without compressed air

- No extraction system required

- No costs for compressed air

- Consistent, reproducible spraying results

- Easy programming of spray patterns

- Low-maintenance, user-friendly system

- High level of process and production reliability

- Installation of up to 2 x 48 nozzles for a maximum spraying width of 4,800 mm

- Applied oil quantities of 0.5 g/m² up to 3.0 g/m² for standard applications

- Can be used for sheet metal feed rates of up to 3 m/s

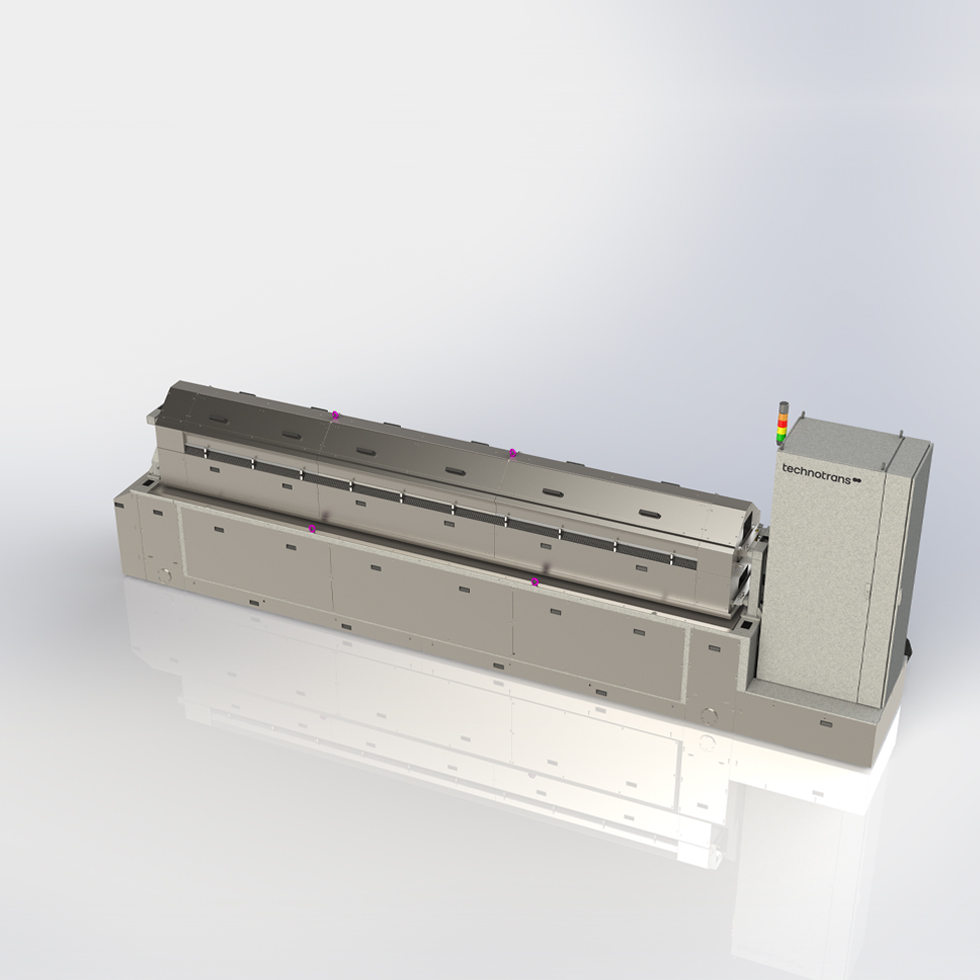

- Consists of a rack, an upper and lower spraying chamber and an integrated control cabinet

- Spray unit can be retracted and extended

- Rack for holding two intermediate oil tanks, one oil collecting tray and several heating elements for preheating the medium

- Oil supply via a separate unit: IBC, drums or via a pipe

- Control system: Own control panel which can communicate with other, superordinate systems via a bus connection, or an external panel

- Quick, automated nozzle test run for the detection of blocked nozzles

- Read-in of CAD files in DXF format, e.g. for the representation of blank contours

- Drawing tool for the independent drawing of blanks