How technotrans

discovered the baking industry.

And vice versa.

The challenge// There is an enticing smell of freshly baked bread and crispy rolls and it smells like creativity. That is because, here, in the production area of Linder Tiefkühlbackwaren, innovative products that have never been made before regularly hit the baking sheets. The family-owned business develops the corresponding recipes itself. „Yes, it is our passion. We want to give fresh momentum to the market and consistently surprise our customers with new pastry delights,“ says Daniel Linder, managing director of Linder Tiefkühlbackwaren.

![[Translate to Englisch:] technotrans Sprühbeölungen [Translate to Englisch:] frischgebackende Brötchen aus dem Ofen](/fileadmin/_processed_/e/8/csm_technotrans-lebensmittelindustrie-broetchen_b45aaeb2c8.jpg)

Production The initial situation

Unhappy with the lubrication of the sheets

Linder produces more than 100 variations of rolls, Danish pastries and puff pastries in Großenehrich, Thuringia. In addition, the company also produces the necessary flour. „Ensuring the constant, high quality of our products is our top priority,“ adds Daniel Linder. „As a result, stable production conditions and parameters are a must.“

However, one of the production steps – the spray lubrication of the baking sheets – increasingly gave rise to objections: Before the products reach the oven, the baking sheets are placed on a conveyor and transported to the spray lubrication station. Here, they are treated with a release agent so that the baked goods do not stick to the sheets after baking. Then, the raw pastries are placed on the baking sheets. Linder was using a conventional spraying system with two-media nozzles but the applied quantities were rather imprecise and the system produced unwanted mist. The result: soiling of the area around the spray lubrication station and an unnecessary high level of release agent consumption.

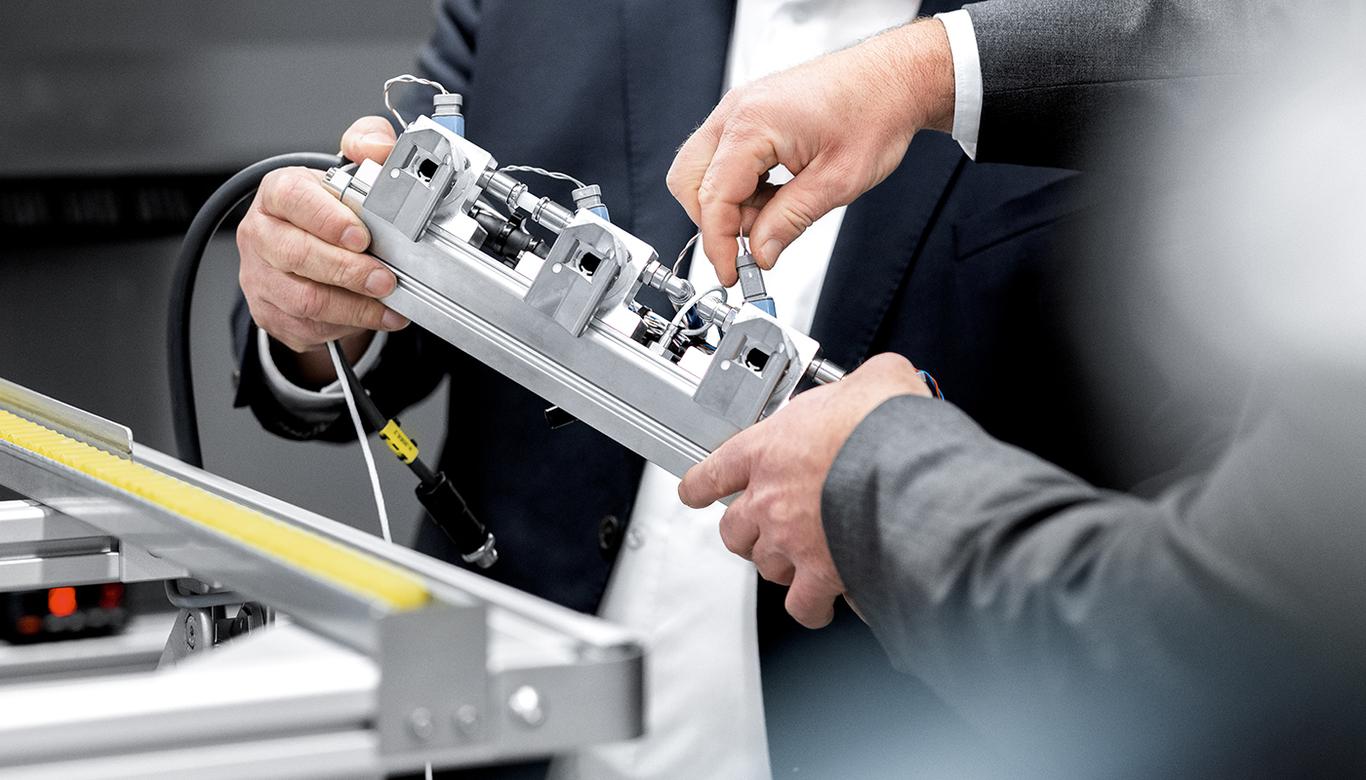

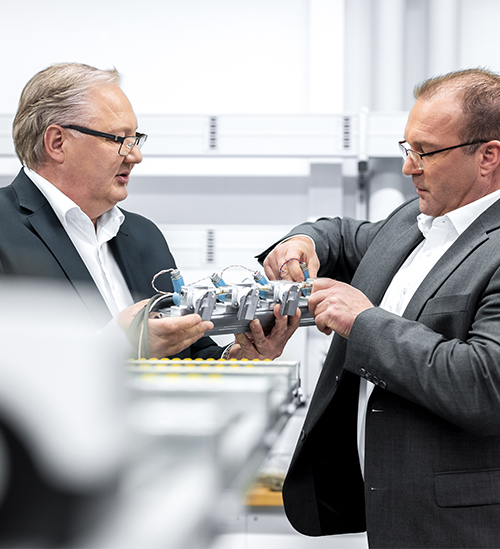

The innnovation power of technotrans// Unwanted mist, imprecise dosing, soiling, high consumption – technotrans has solved all the problems at once with a completely new solution. An innovation that resulted in outstanding precision, consistency and efficiency for the entire production and that has everything it takes for a widespread successful use throughout the baking industry.

The spray.xact spray lubrication system made by technotrans stands out due to its extremely precise, low-mist oil application enabling Linder to reduce the release agent consumption by 30% and preventing unwanted deposits and residues in the production area. What are the special features of this solution? technotrans was able to use a well-established technology for the spray.xact system: It is based on a proven technotrans spraying concept which originates from the punching and forming sector and has been specifically adapted to the requirements of food producers.

![[Translate to Englisch:] Innovation technotrans [Translate to Englisch:] Zwei Personen inspizieren eine Lebensmittelmaschine](/fileadmin/_processed_/7/3/csm_technotrans-lebensmittelindustrie-maschine-gross_d6e9949012.jpg)

»A completely new player in this industry – and immediately such a great success?

That`s is very impressive!«

![[Translate to Englisch:] Spühbeölung mit Einzelansteuerung der Ventile [Translate to Englisch:] 3D Bild einer Spruebeoelungsanalge](/fileadmin/_processed_/9/9/csm_technotrans-lebensmittelindustrie-maschine-3d_2b5f2e1dab.jpg)

![[Translate to Englisch:] Prozesssicheres System [Translate to Englisch:] Bedinungselement einer Spruebeoelungsanalge](/fileadmin/user_upload/Stories/Story_03_Lebensmittel/technotrans-lebensmittelindustrie-maschine-3d-logo.jpg)

![[Translate to Englisch:] Sprühbalken [Translate to Englisch:] 3D Animation eines Sprühbalken](/fileadmin/user_upload/Stories/Story_03_Lebensmittel/technotrans-lebensmittelindustrie-maschine-3d-freisteller-2.jpg)

| Picture above: | Individual nozzle control |

| Picture bottom left: | Process safe system |

| Picture bottom right: | Spray bar |

»Please keep up the good work!«

Advantages

Higher product quality with reduced material usage

„The system ensures a high level of reproducibility as the dispensed medium quantity always remains constant regardless of the ambient conditions," says Hary Kosciesza, Business Development Manager of technotrans. Daniel Linder adds: „The technotrans solution enables us to apply minimal oil quantities with a very high level of precision to fulfil the most stringent hygiene standards and to further improve our product quality“.

Thanks to its special high-frequency valves, the spray.xact system does not require any compressed air. As a result, the system does not produce any mist and there is no need for integrating an extraction system. Another advantage: the temperature of the valves can be controlled with a high level of precision, thereby keeping the viscosity of the applied release agent at a low level which, in turn, guarantees a precise spray pattern – regardless of the ambient temperature.

Advantages

Handling of oily, sticky and many other types of media.

However, the system is not only perfect for applying oily release agents. It can actually handle a wide range of different media: During an initial test at Linder, the spray.xact system was used for applying sugary glazing to pastries and managed this task just as precisely.

During the project, technotrans provided all the services with its own manpower: from project planning and commissioning to the on-site technical training of the Linder employees. Due to the overwhelming success, Linder Tiefkühlbackwaren has already decided to continue working with technotrans: „We are very happy about the results and uncomplicated relationship and, therefore, we plan to equip all our remaining production systems with the technotrans solution,“ says Daniel Linder.

The development of a spraying system for the food industry is only one of numerous examples showcasing how technotrans transfers its longstanding expertise to other, new industries. Through attentive market research and analysis, and by intelligently transferring proven technologies to other areas of application, technotrans will continue to conquer more and more new markets in the future.

»technotrans ... a name

to remember.«

Do you have any questions?

We have the answers.

Hary Kosciesza

Business Development Manager

T. +49 (0)2583 301-1850

hary.kosciesza@technotrans.de