Automotive innovation thanks to

variothermal temperature control

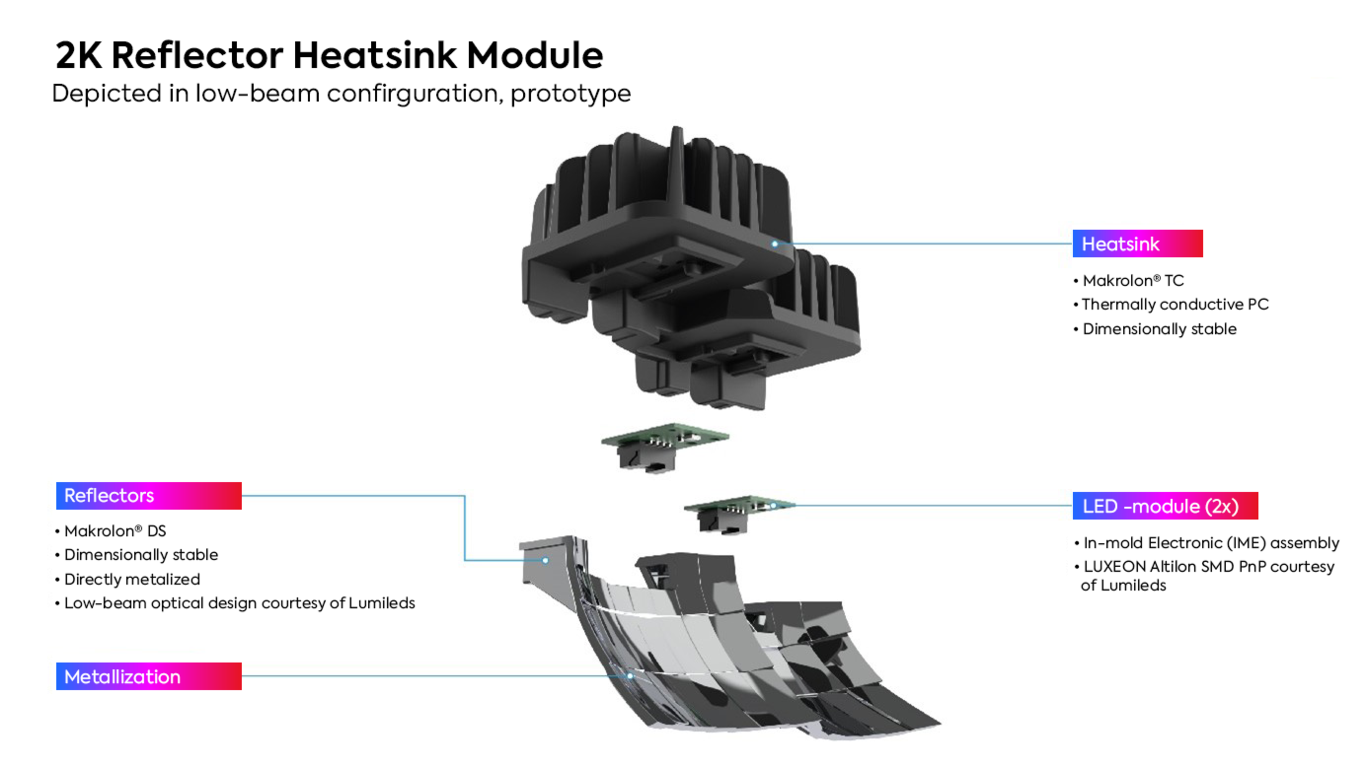

The material manufacturer Covestro relies on a dynamic temperature control solution from technotrans for the production of a highly integrated LED low-beam module including a thermoplastic heat sink.

The challenge// Vehicle manufacturers are faced with the challenge of developing headlights that optimally combine brand identity, aesthetics, performance and safety. At the same time, they need to keep an eye on costs, as materials and manufacturing processes have a significant impact on overall costs. Covestro and Lumileds Germany GmbH joined forces to develop an innovative LED low-beam module that meets these requirements. In doing so, they had to solve issues relating to LED integration, surface quality and stability under high thermal stress.

Challenge Surface quality & energy efficiency

Variothermal thermal management for injection molding

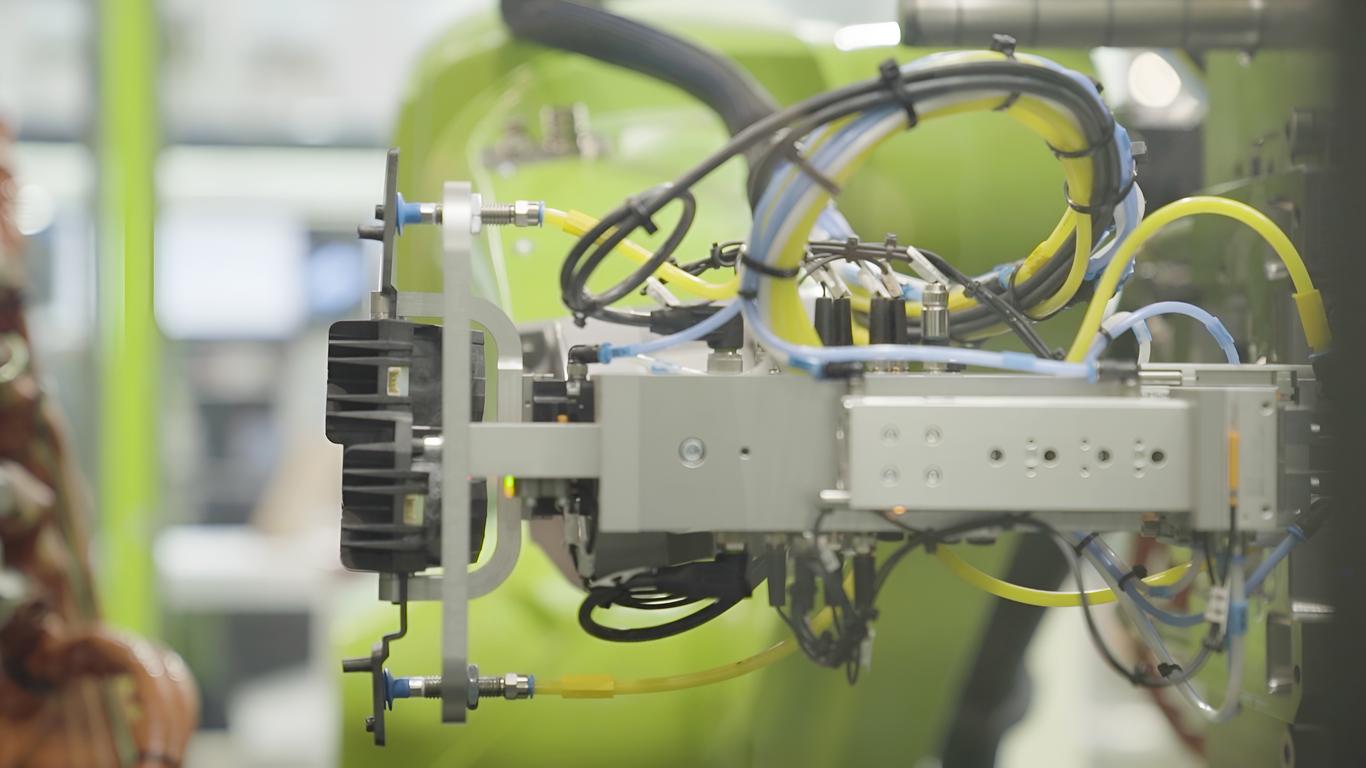

The variothermal temperature control solution from technotrans plays a decisive role in achieving the desired glossy, highly reflective surface. The injection molding process runs in a variothermal mode, which means that precise temperature control is crucial in order to achieve a consistently high image accuracy.

technotrans innovation//

Precise temperature control in a highly integrated production process

With its new variothermal temperature control solution, technotrans enables the energy-efficient production of high-quality molded parts in plastics processing.

In the manufacturing process, Covestro uses two-component injection molding in combination with the integration of electronic components using in-mold electronics (IME) and a subsequent metal coating. IME technology enables the direct embedding of electronic components in plastic or other substrates during the molding process. The use of conventional temperature control solutions results in a matt, uneven surface.

technotrans' precise temperature control enables Covestro to achieve the desired glossy, highly reflective surface, thus generating significant efficiency gains and expanding the manufacturer's design scope.

A notable feature of this solution is the integration of a highly efficient energy storage and control unit, which enables considerable energy savings compared to conventional systems.

Advantages

at a glance

Cost efficiency

The new thermoplastic solution optimizes the production and significantly reduces post-processing and assembly steps.

Weight-optimized

Compared to conventional units, the low-beam module is around 40 percent lighter.

High luminous power

The technological solution ensures a glossy, highly reflective surface for stable light output.

Energy efficiency

The variothermal temperature control solution from technotrans saves energy and ensures an efficient injection molding process.

Environmental friendly

The innovative production improves the ecological balance and minimizes the footprint of the LED low-beam module.

Reliable thermal management

technotrans offers an integrated solution to ensure process stability and precision.

»Effective thermal management must always be considered holistically in order to achieve the greatest possible process stability, precision and efficiency.«

Carsten Schmidt, Sales Manager Temperature Control

Conclusion// One of the success factors for the joint project is the many years of trusting cooperation. The joint development, in which the technological solution expertise is always brought to bear in a targeted manner, is particularly valued.

"We have been working with technotrans for several years now and particularly value the joint development, in which the company always contributes its technological solution expertise in a targeted manner," emphasizes Rainer Protte, Head of Advanced Injection Molding at Covestro.

Following the very successful debut at K 2022, both companies will be presenting the process innovation at Equiplast in Spain and Plastimagen in Mexico in 2023. Carsten Schmidt emphasizes the great pleasure of supporting Covestro with technotrans' thermomangement expertise.

»After several joint projects, this innovative concept was a real highlight.«

Do you have any questions?

We have the answers.

Carsten Schmidt

Sales Manager Temperature Control

T. +49 (0)2354 7060-300

carsten.schmidt@technotrans.de